The ever-changing capacitor market offers more than meets the eye

Capacitor makers today are focused on meeting the needs of more-powerful high-speed processing. The capabilities most in demand by circuit designers—lower inductance, higher capacitances, smaller package sizes, and lower ESRs—contribute to the faster, safer, and more-efficient operation of microprocessors found in computers, servers, routers, automobile computer systems, and even cell phones.

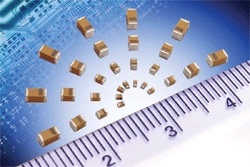

Meeting the industry's miniaturization trends, tantalum capacitors have finally ventured into 0402 case sizes.

Low inductance

One of the issues central to increased performance of microprocessors—and therefore more in demand by component manufacturer customers—is lower inductance in the system's capacitors. Current flow during the simultaneous switching of logic gates in digital circuits generates voltage fluctuations across power supply buses.

The magnitude of these fluctuations depends on the amount of current, rise times, and the effective chip and package inductance. This power supply noise can couple through a logic-circuit driver and appear as a spurious voltage signal on the input terminals of a logic-receiver circuit, sometimes causing logic-switching errors.

The trend in the electronic industry toward higher-frequency switching, decreased pulse-rise times, and increased circuit density exacerbates the simultaneous switching problem to the point that it can become a serious limitation to improved system performance. The most common way to manage this noise problem is to use capacitors that act as local energy sources to provide the voltage required to switch and refresh logic gates. These capacitors are decoupled from both the power supply with its associated noise spikes and from the package inductance.

However, decoupling capacitors can themselves generate voltage spikes—a problem many capacitor manufacturers are trying to solve. One such solution, for example, focuses on the direction of the electrode current flow required to charge the dielectric.

In a standard surface-mount capacitor, the charging current flows from one termination down the electrode into the dielectric and out into the counter electrode. The total path of the port current—the length of the capacitor—determines the inductance.

So some manufacturers design lower-inductance surface-mount capacitors by terminating the electrodes along the device's longest side, producing 0612- instead of 1206-size devices—or 0508 instead of 0805. Lower inductance can be taken a step further by creating an interdigitated capacitor, typically an 8 to 10-terminal device with alternating polarity of each terminal to further reduce the current path.

More CV, smaller packages

One of the overall trends in component design, in general, has been smaller package sizes. For capacitor manufacturers, this often means increasing capacitance in a particular case size—or offering existing performance in ever-shrinking packages.

The industry has achieved 0603 and 0402 in the tantalum market, and ceramic manufacturers have shrunk the size to 0201, with 01005 close behind. The challenge faced by component manufacturers is shrinking the case sizes without sacrificing capacitance.

Following growing customer demand, products such as a 0402 tantalum capacitor have been developed that deliver up to 10 µF. In ceramic capacitors, the development of thinner dielectrics has allowed the ready availability of such products as a 1210 100-µF device and a 0402 1-µF part.

Greater durability

As applications become more powerful, the need for more-rugged more-durable parts increases as well. One of the issues faced by the electronics industry in general (and the automotive industry in particular) is that capacitors crack when the boards on which they are placed are flexed and strained.

The most common mode of failure for board-mounted ceramic capacitors, cracking results from the nature of the ceramic material, from mishandling capacitors during assembly, or from extreme environments,. A board's flexing may result from mechanically induced forces during assembly manufacturing, as well as from harsh operating conditions in the field.

In a worst-case scenario, a low-resistance fracture failure can lead to extremely high temperatures when the component is connected to a power line, and with ample current supply, the result could be catastrophic damage to the immediate area of the circuit board. Because of the safety issues involved, component manufacturers are focusing on designs that will make capacitors more durable in these situations.

An example of one of the solutions currently being employed is the use of an additional flexible termination layer added to the component to ensure electrical integrity when external forces are applied. Typically, board flex-induced cracks initiate where the ceramic-termination interface is soldered onto the pc board and propagates to a point about halfway up the height of the ceramic capacitor termination.

The addition of high-conductivity termination material to a standard X7R dielectric ceramic capacitor not only solves cracking problems in extreme-environment situations. But if a crack were to occurred and the capacitor failed, it would be in the termination area and in open mode, meaning little or no degradation to the capacitor's performance.

Shorts, along with temperature, are significant concerns to designers who must deal with heat generated by the faster more-powerful microprocessors that are being continuously developed. Recent legislation in Japan requires that computer boards do not smoke or burn, so most PC manufacturers want to use components that greatly reduce the risk of these occurrences.

Burning is also a major safety issue for automotive manufacturers. Capacitor manufacturers are assisting with these challenges by developing new nonburning materials for use in capacitor design. An example of this would be niobium oxide capacitors—the first new dielectric developed in more than 40 years. Because of the high reliability and safe failure mode of the niobium oxide, these capacitors are derated at only 20% instead of the standard 50% for similar components.

Lower ESR

Another key parameter for circuit designers is ESR. Ceramic capacitors have inherently low ESR because of their design and materials.

To get low ESR in tantalum capacitors, manufacturers have developed polymer and multianode capacitors. The multianode capacitor provides a component that replaces up to three single-anode capacitors, with the added benefit of saving board space and placement costs.

More important, performance is not sacrificed because such capacitors deliver low ESR, high capacitance, and high ripple capacitance. Delivering ESR down to 30 mW, such a solution is ideal for power supply decoupling and high-speed data-processing applications. |